12 Years Experience In The Industry

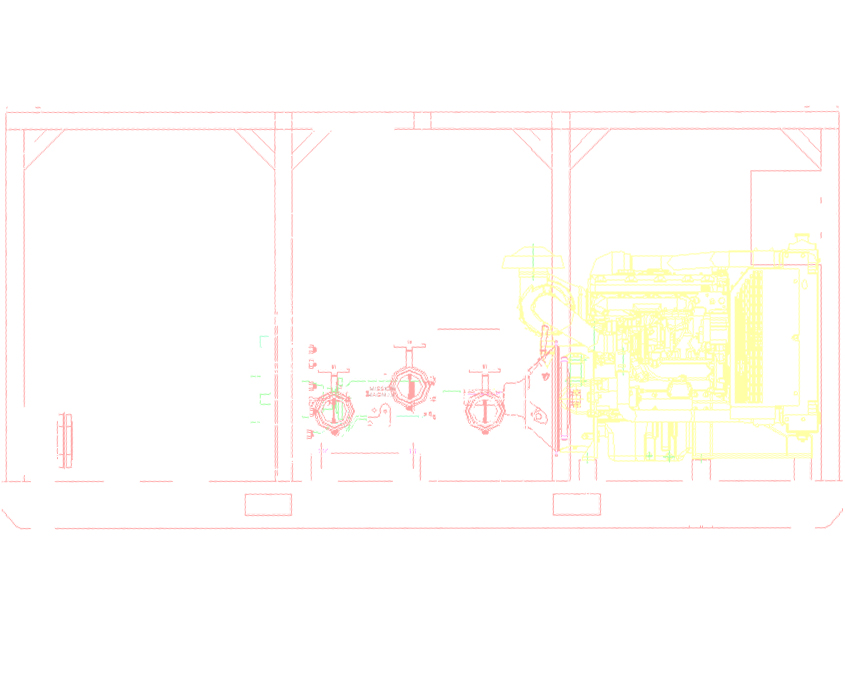

150 bbl Batch mixer tank containing

- L 5.5 m x W 2.45 m x H 2.00 m

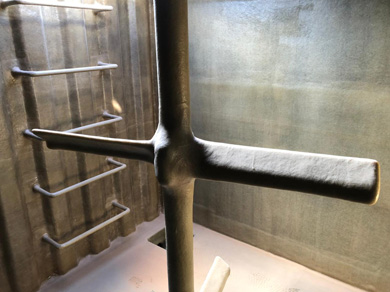

- Top-mounted agitators with inside fan blabbed, each 12 hp.

- Suction manifold 4 with SS discs butterfly valves.

- Filling manifold 3 with SS discs butterfly valves.

- Top-mounted handrails.

- All coated with Derakane lining 430.

- Two (2) SS magnetic level gauge.

- All SS cam-lock fitting 2 for chemical injection.

100 bbl mutual solvent tank containing

- L 3.5 m x W 2.45 m X H 2.00 m.

- Single compartment.

- Suction line 4 with standard butterfly valve.

- Filling line 3 with standard butterfly valve.

- One (1) SS magnetic level gauge.

Chemical tanks containing

- Qty (7) tanks (NI-18, ASA-5, NSA-1, HSS, NIC-02, NDE-11, and D-solvent).

- 2 mm SS tanks from Hoover & Ferguson.

- Filling line with 1 cam-lock fitting.

- Suction line with 2 SS ball valve.

- One (1) SS magnetic level gauge.

Discharge & filling & flushing manifold

- All of 2 SS fittings.

- Each tank shall have Qty (2) ball valve, check valve, and required fittings.

- Filling manifold from each drum to all tanks.

- 2 chemical hose connecting all tanks flushing lines.

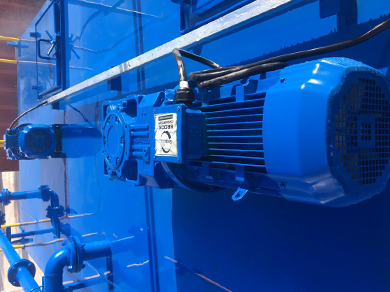

Suction pumps

- Seal-less PVD centrifugal pump, 125 lpm, with 1 hp motor.

- Discharge fitted with Muis Canada 1 SS turbine flow-meter.

Barrel motorized pump

- Qty (3) PDV seal-less motorized pumps.

- Capacity 80 lpm with 0.75 hp motor.

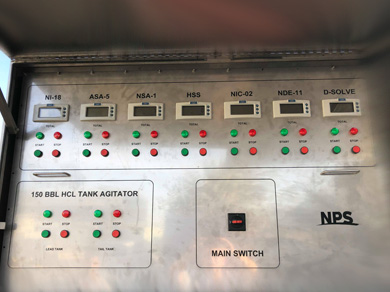

Control panel

- Control ON/Off switches for all motors consolidated in one panel.

- The panel is an SS box with SS engraved fascia, labeled for each chemical type pump.

- Flow-meters of Muis Canada installed on the panel for each tank.

- All switches are of Schroeder Germany make.

- Enough cables supplied for main power, and each pump from the panel.

Chemical tanks structure

- Made of MS tubes in (3) separate pieces.

- Two (2) frames for the chemical tanks stand.

- One (1) frame centrally located for walkway, covered with GRP fireproof grating.